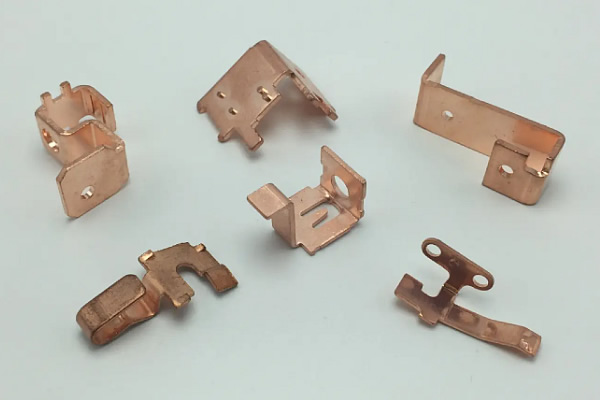

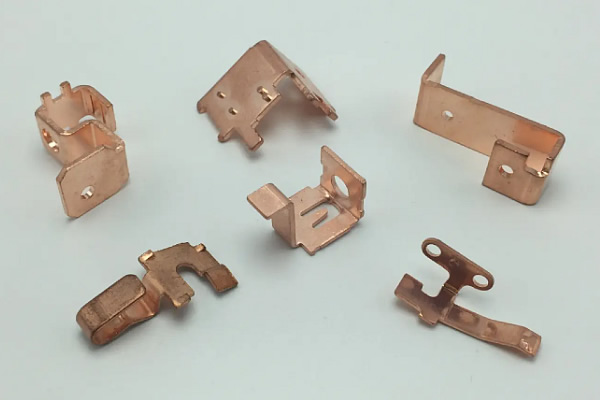

The so-called precision hardware processing refers to the processing and production of precision hardware raw material products, usually through the processing of precision hardware to produce component products with precision density between 0.05mm. Precision hardware processing can be divided into precision plastic hardware processing, precision stamping hardware processing, and precision turning hardware processing. Below, the editor will introduce the content about the precision hardware processing process and precautions. Welcome to read!

Precision hardware processing process flow:

1. Material opening: Book steel materials from the material supplier according to production needs, and then proceed with material opening processing;

2. Testing: After cutting the material, perform tolerance testing on all four sides;

3. Processing: After the inspection is completed, it can be directly taken to the punching machine for milling or CNC machining. This step is extremely important and requires meticulous attention. The quality of the processing determines the quality of precision hardware processing products;

4. Surface treatment: Often, after precision hardware processing, further polishing, oil spraying, or electroplating treatment is carried out on the surface of hardware components to improve the quality of the product and increase its service life;

5. Shipping: When all processing and surface treatment are completed, assembly can be carried out, and then the shipment can be completed perfectly.

Precautions for precision hardware processing:

1. Accurate design drawings are required.

Just now, precision hardware processing is the processing of some small diameter hardware parts, so the design drawings of this product need to be accurate, and the parts will lose thousands of miles. If the drawings are not accurate, the produced parts may not be usable, thereby increasing production costs.

2. Precision hardware processing materials.

Precision hardware processing products are generally used in places such as aviation and watches that require high material quality, therefore the quality requirements for processing hardware products are also high. Therefore, precision hardware processing generally uses high-quality materials.

3. Cost budget.

In many cases, the price of precision hardware processing products is relatively low, so we should also consider this in our budget, which requires precision hardware processing to control costs. Improving production technology and improving production efficiency plays an important role in cost control.

Precision hardware processing is a process with high requirements for various aspects, but as long as these precautions are met, it can generally be done well.

15307699242

15307699242